-

Shop

-

Learn to make

-

Help Center

-

About

- Tuft in Residence

- Reflect Rewards

- Custom rugs

-

February 19, 2026

The scissors on your AK-I, or DUO machine might not be adequately cutting for one of the following reasons:

1. The yarn you're using is too soft, so the fibers are bending against the scissor blade instead of severing. Tufting machines work best with coarser yarns, especially wool. Read more about ideal tufting yarns here.

2. Fibers might’ve built up in the scissor channel of your machine. Be sure to brush our shed fibers from all parts of your machine as part of regular maintenance.

3. The machine has been adjusted incorrectly or over-extended during a pile-height change, causing the scissors to malfunction.

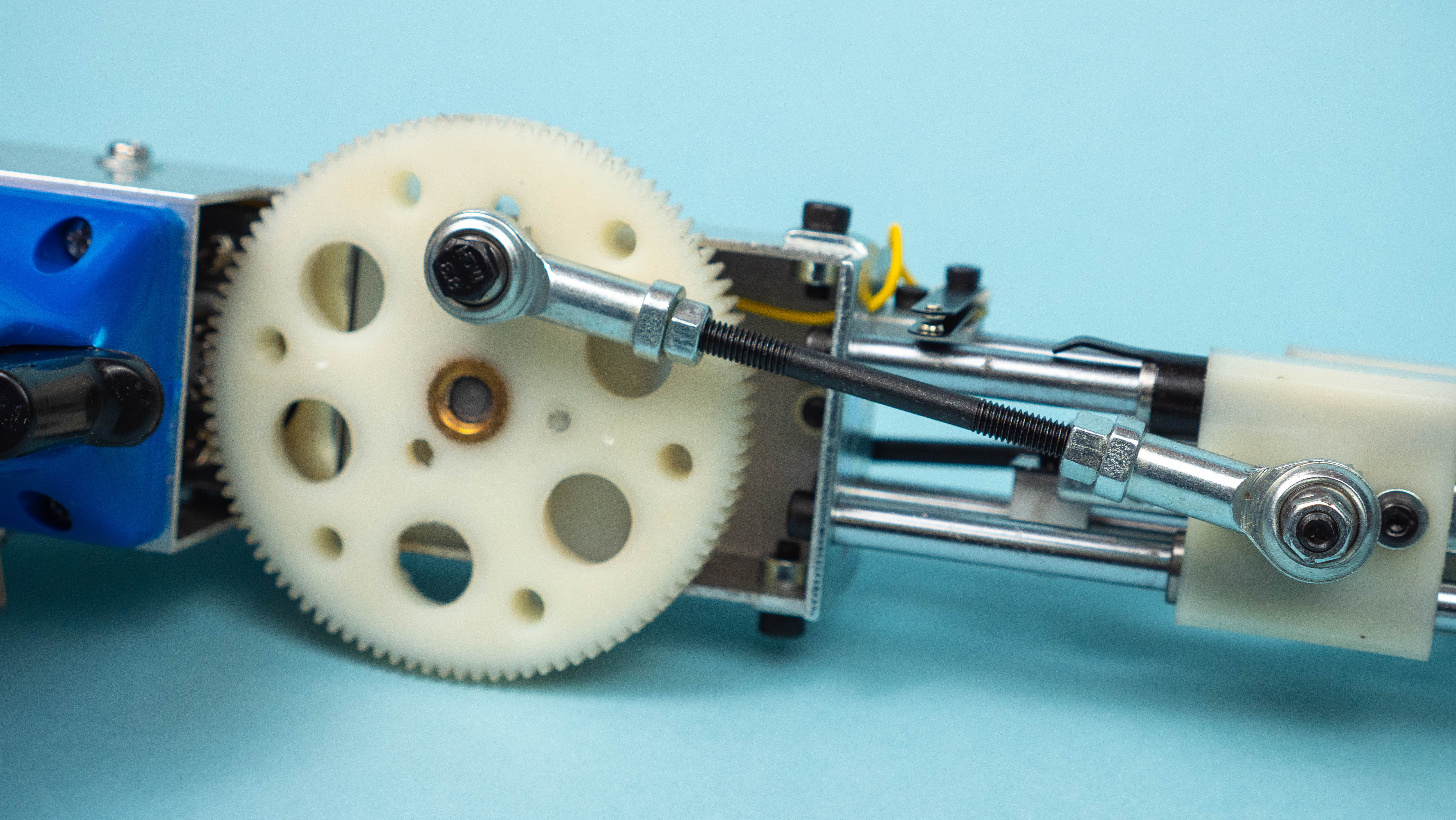

4. The scissor action is a mechanical process, meaning when the open scissors are moving back and forth, they hit a metal piece at the front of the machine, the scissor-closer, which causes them to close (see video below). If the scissors appear stuck or jammed, it means that the scissor-closer might need a micro-adjustment to push the scissor blades together.

5. Your scissors are dull and need to be replaced; this happens over time, especially if you tuft often and with fibers other than wool. Contact support@tufttheworld.com to request a replacement scissor piece, and we will e-mail you an invoice to set up your order.

6. The foot of your machine was not micro-adjusted correctly, thus preventing the scissors from performing the cut-action at the right point of contact while tufting. Revisit step 3 of the AK-I pile-height adjustment article for more information.

If these changes still don’t solve the issue, contact us at support@tufttheworld.com.