-

Shop

-

Learn to make

-

Help Center

-

About

- Tuft in Residence

- Reflect Rewards

- Custom rugs

-

February 19, 2026

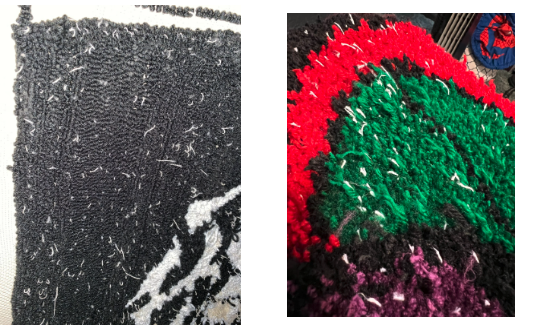

It looks like your machine is cutting the cloth, or tufting little bits of it into your rug. You can always pull these strands out before you glue, but that doesn’t solve the underlying issue!

There are two main reasons this might be happening:

This could be a pressure issue. If the machine is not pressed firmly enough against the cloth, the scissors will catch the cloth as they come out and cut it. Same goes for the yarn bulging out on the back - if you aren’t pressing hard enough, the yarn will build up on the back . Read our quick start guide for tips on tufting

If pressure is not your issue, then it’s probably this common minor foot adjustment! The foot and the needle work together and need to be lined up correctly. This article on pile height adjustment includes a video on how to adjust the needle to achieve this correct alignment

To set the foot/needle relationship:

February 19, 2026

If your yarn won’t “stick” in the tufting cloth, try following these tips:

February 19, 2026

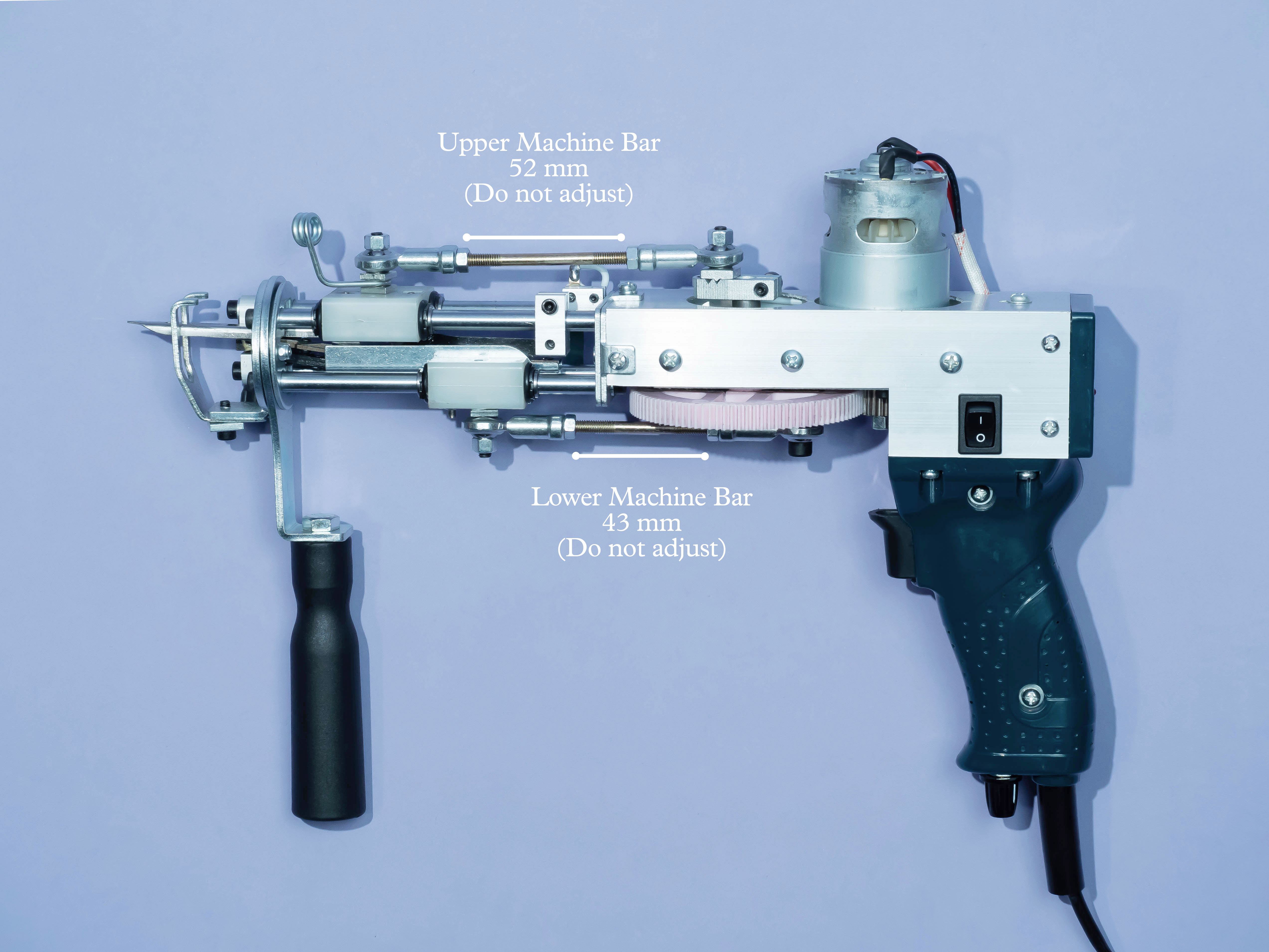

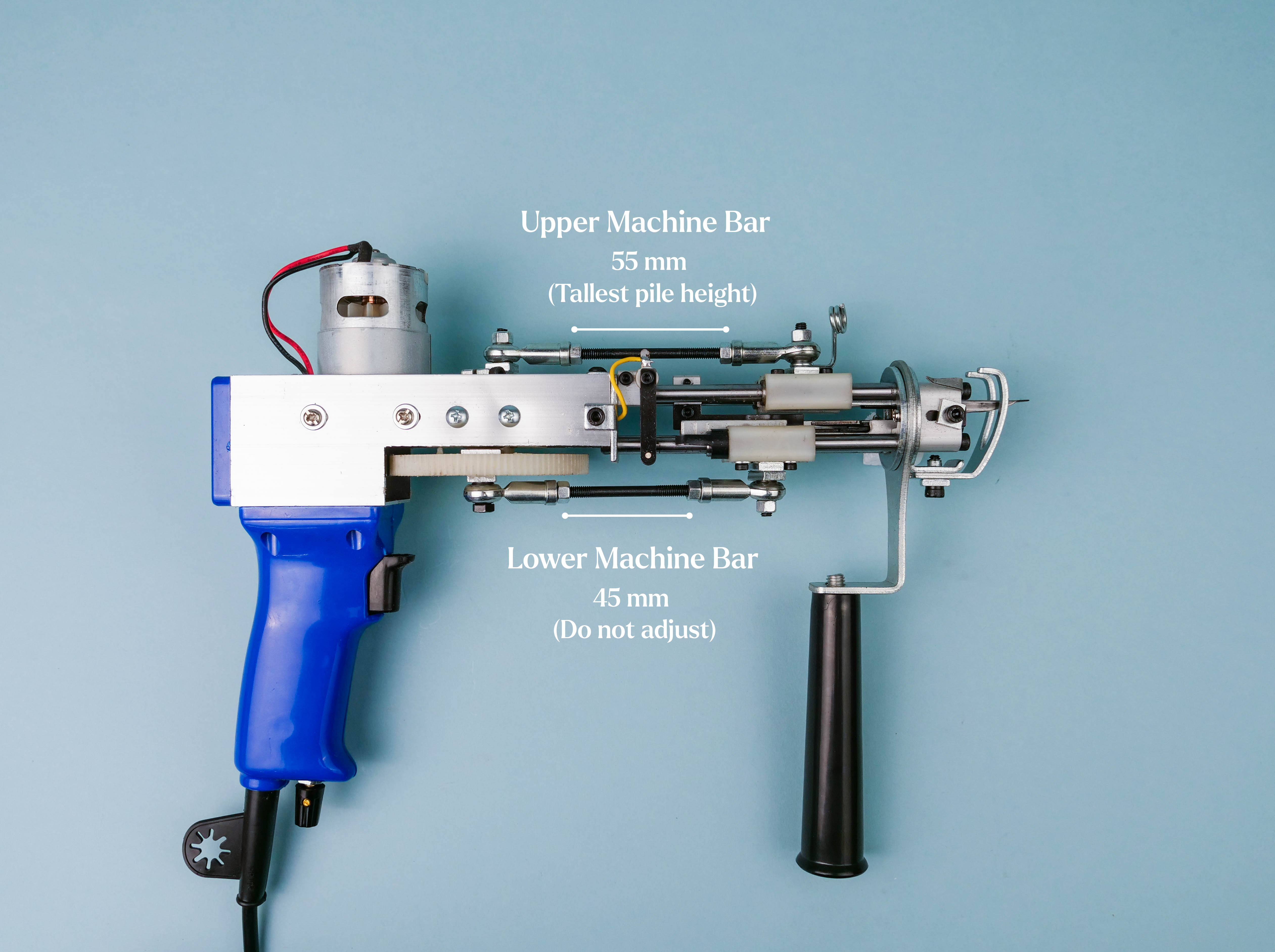

In order to tuft properly, all parts of your machine must be synchronized so that the needle and nozzle push the cloth open to create a tuft. Even a few millimeters of maladjustment can cause the machine to fall out of sync, creating problems.

If your machine is out of sync, it’s probably because a pile-height adjustment was made incorrectly. Luckily tufting machines are durable, and can often be fixed simply by reestablishing the factory settings of the upper and lower machine bars.

Factory settings for Duo machine:

The factory setting should not be moved on the Duo. For step-by-step guidance on how to adjust the pile height on your Duo, check out the video collection that came with your machine.

Factory settings for AK-I Cut-pile Machine:

The factory setting is also the tallest pile height on the AK-I. For step-by-step guidance on how to adjust the pile height on your AK-I, check out this article and video.

Factory settings for AK-II Loop-pile Machine:

The factory setting is also the shortest pile height on the AK-II. For step-by-step guidance on how to adjust the pile height on your AK-II, check out this article and video.

To change the pile height on your KRD-I, you’ll need to either extend or shorten the machine’s upper machine bar. Find step-by-step instructions here.

February 19, 2026

Your machine might squeal for one of the following reasons:

Needs Oil: Tufting machines require regular oiling to function properly. We recommend using sewing machine oil (best option), 3-in-1 multipurpose oil, or another lubricating oil at least monthly. Learn more on how and where to oil your machine here.

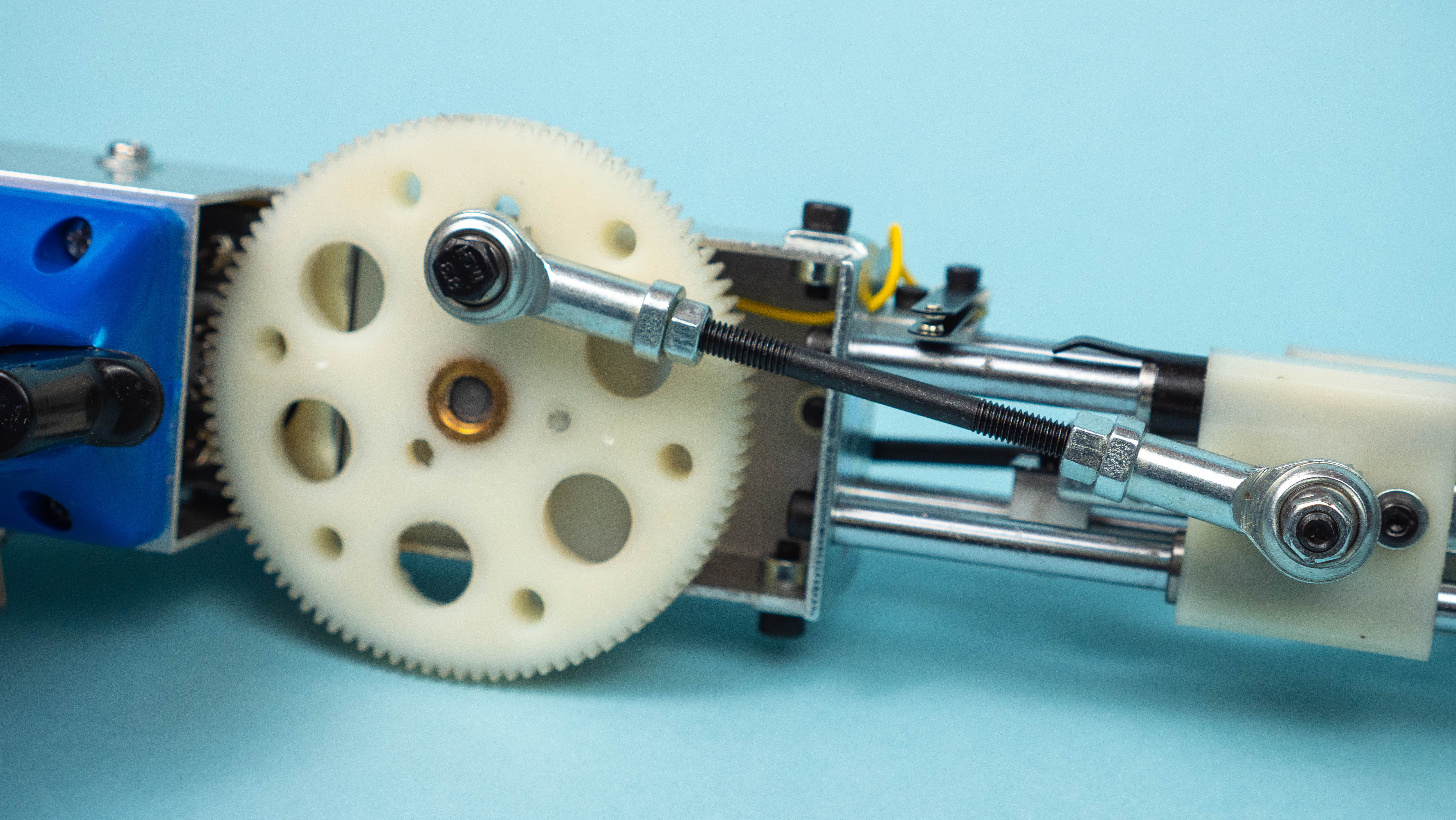

Yarn Jam: If there's yarn stuck in the gear of your machine, or if the square bearings that control the tufting action are stuck, contact support@tufttheworld.com for troubleshooting assistance, or to send your machine in for repair.

Electrical Issue: If yarn isn’t visibly stuck in the white (AK-I and II) or pink (DUO) gear or square bearings of your machine, the issue is most likely electrical. Email us support@tufttheworld.com for troubleshooting assistance, or to send your machine in for repair.

February 19, 2026

The scissors on your AK-I, or DUO machine might not be adequately cutting for one of the following reasons:

1. The yarn you're using is too soft, so the fibers are bending against the scissor blade instead of severing. Tufting machines work best with coarser yarns, especially wool. Read more about ideal tufting yarns here.

2. Fibers might’ve built up in the scissor channel of your machine. Be sure to brush our shed fibers from all parts of your machine as part of regular maintenance.

3. The machine has been adjusted incorrectly or over-extended during a pile-height change, causing the scissors to malfunction.

4. The scissor action is a mechanical process, meaning when the open scissors are moving back and forth, they hit a metal piece at the front of the machine, the scissor-closer, which causes them to close (see video below). If the scissors appear stuck or jammed, it means that the scissor-closer might need a micro-adjustment to push the scissor blades together.

5. Your scissors are dull and need to be replaced; this happens over time, especially if you tuft often and with fibers other than wool. Contact support@tufttheworld.com to request a replacement scissor piece, and we will e-mail you an invoice to set up your order.

6. The foot of your machine was not micro-adjusted correctly, thus preventing the scissors from performing the cut-action at the right point of contact while tufting. Revisit step 3 of the AK-I pile-height adjustment article for more information.

If these changes still don’t solve the issue, contact us at support@tufttheworld.com.

February 19, 2026

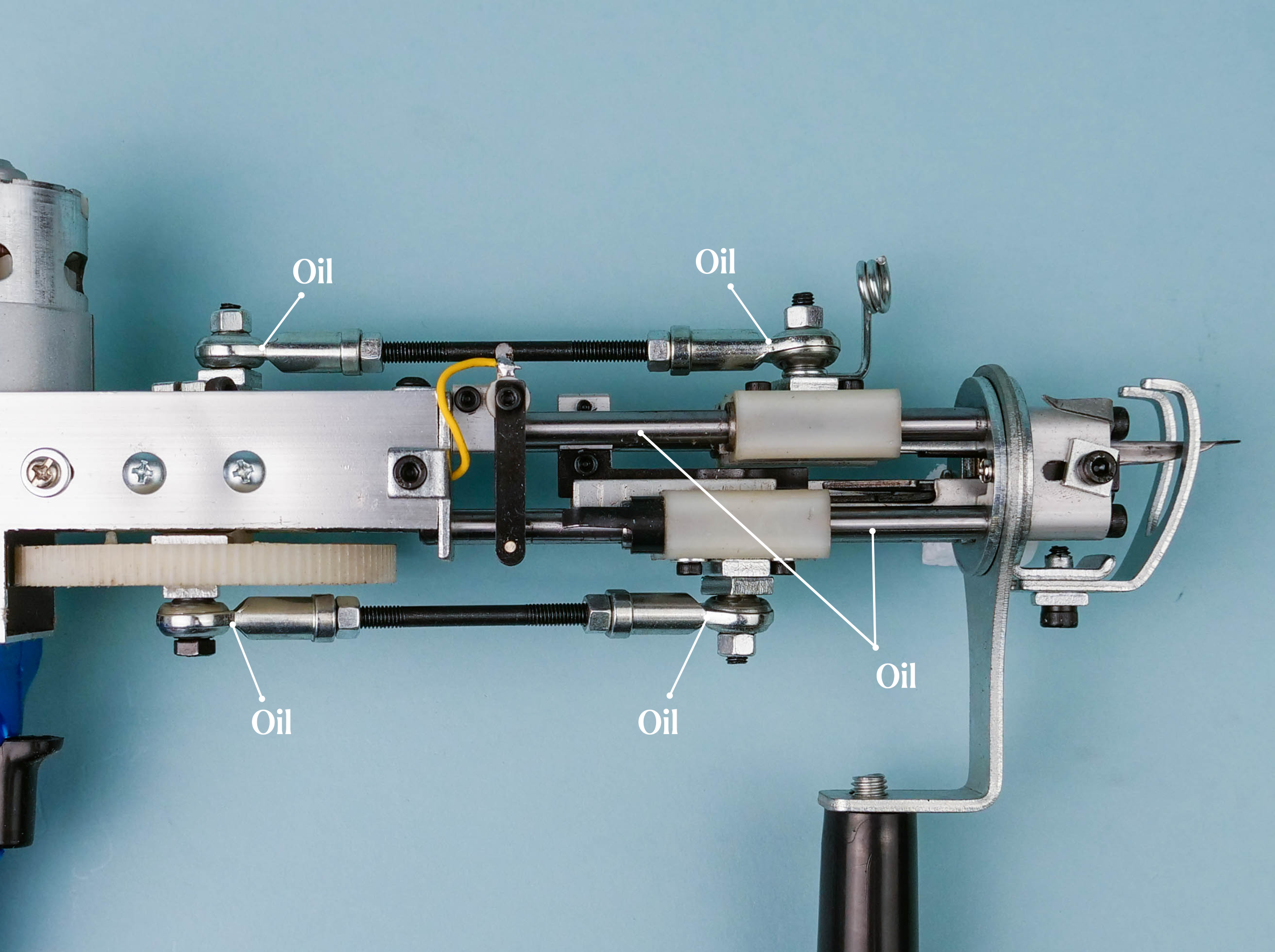

The most basic element of machine maintenance is regularly oiling your tufting machine, regardless of the model. You should oil your machine each time you use it. We recommend using sewing machine oil (best option), 3-in-1 multipurpose oil, or another lubricating oil.

To oil your low-pile machine (AK-I, AK-II, all DUOs, KRD):

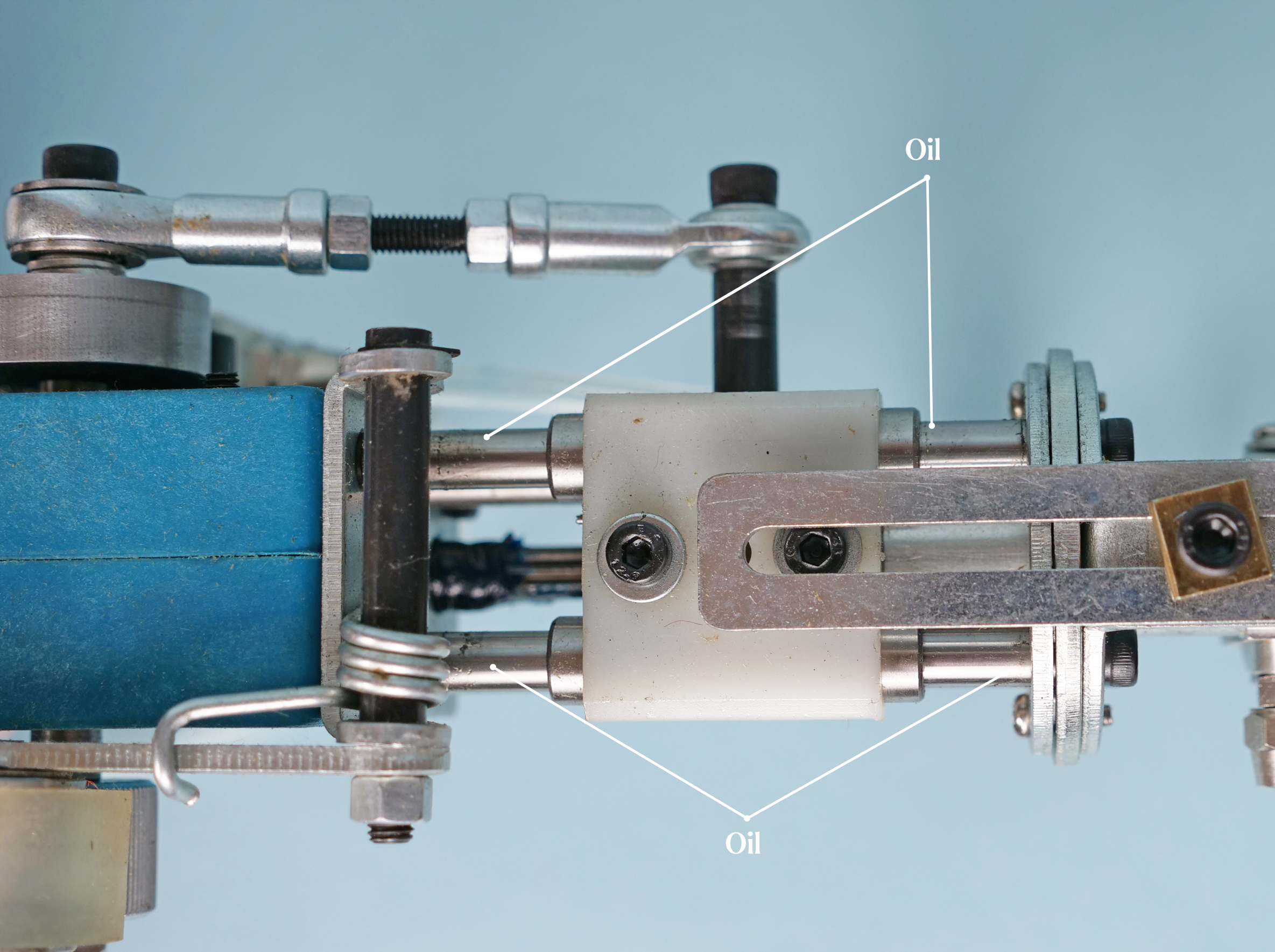

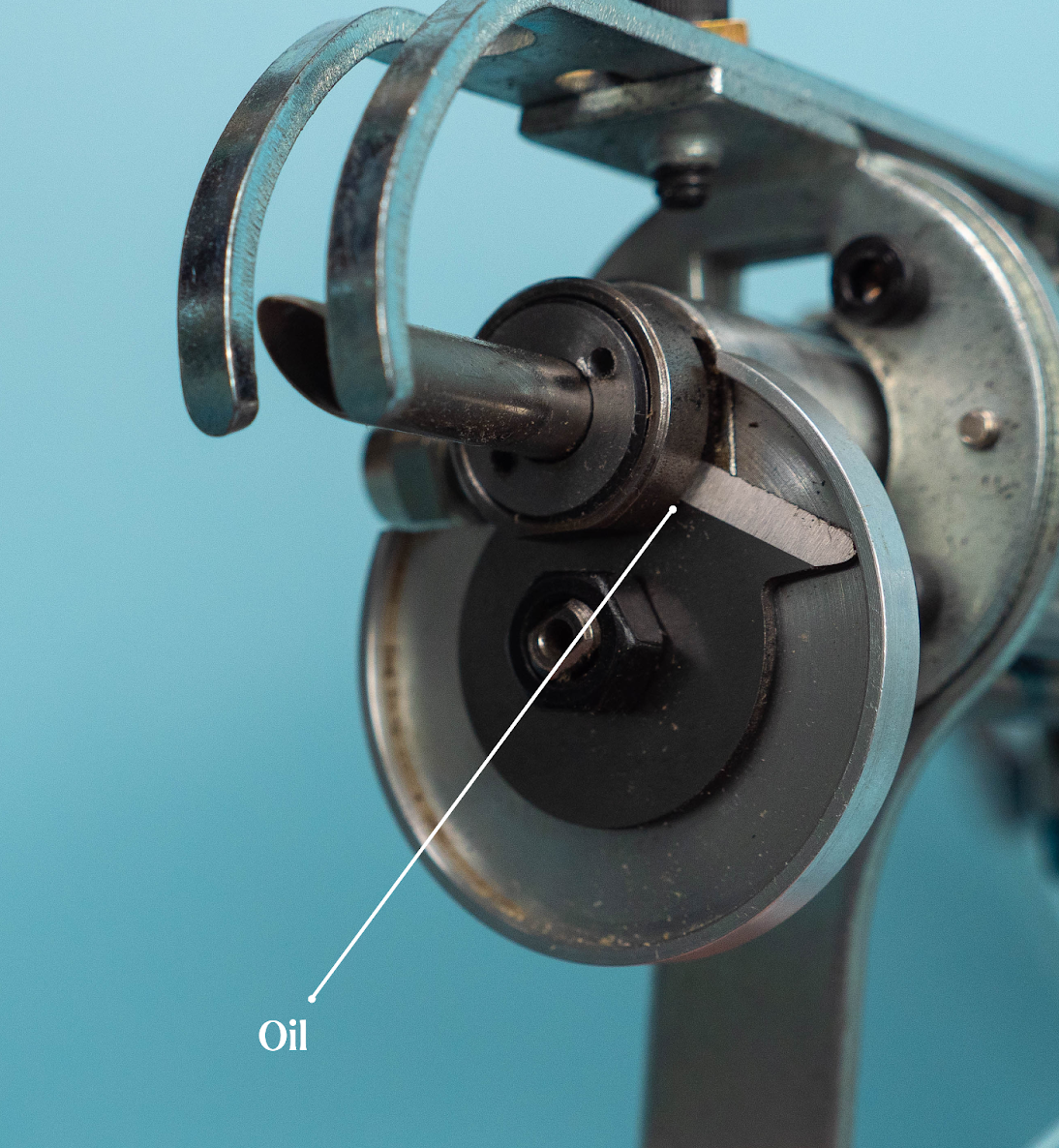

As a general rule, apply oil to every part of your low-pile machine that moves. On the AK-I, AK-II, all DUO machines and KRD-I machines, apply a few drops of oil to the metal bars in front of and behind the white square bearings, and to the rotating bearings at the ends of the upper and lower machine bars. Turn the machine on to evenly distribute the oil, adding additional drops as needed until the machine runs smoothly. You can’t over-oil, so don’t be shy.

To oil your high-pile machine (AK-III):

High-pile machines need to be oiled more frequently than low-pile machines because they run at higher speeds. We recommend oiling your high-pile machine every few weeks.

As a general rule, apply oil to every part of the AK-III that moves. Focus on the metal bars in front of and behind the white square bearings, and the blade near the needle. Turn the machine on to evenly distribute the oil, adding additional drops as needed until the machine runs smoothly. You can’t over-oil, so don’t be shy.